Yashica Lynx 5000

The Yashica Lynx series of cameras are fixed lens, leaf shutter rangefinder cameras made in the 1960s. These cameras are well made, all metal body cameras with excellent lenses and are often underpriced for their performance. The Lynx models were the 1000, 5000, 5000e, 14 and 14e. All of these cameras have built-in meters, full manual settings, and very good Yashinon lenses. The 1000, 5000, and 5000e have a f/1.8 Yashinon lens. The 14 and 14e have an excellent, very fast f/1.4 lens. The Yashica "J" camera is very similar to the Lynx 1000, but has a simpler shutter, 1:2.8 lens, and no built-in meter.

The first camera, the Lynx 1000, had a selenium cell to directly drive a galvonometer. In the Lynx 5000 the selenium cell was replaced with a CDS cell and requires a 625 mercury battery to operate. (Although mercury batteries are no longer available, I have gotten good results with zinc-air hearing aid batteries.) The Lynx 14 was an improved version of the 5000 that used an f/1.4 lens. Later in the 5000e, the galvonometer was replaced with an electronic metering system that displays over and under indicators in the viewfinder instead of the meter needle. The Lynx 14e has the same f/1.4 lens as on the Lynx 14 but uses the two display lights as on the 5000e. The 14e and 5000e use two 640 size batteries instead of the 625 battery. On these two models, alkaline batteries will give good exposures. Joe Wolf offers an adapter that replaces the hard to find 640 batteries.

In all cameras, the exposure setting is done manually. To set an exposure, you press a switch on the front to turn on the meter and then adjust the shutter speed and/or aperture until a proper exposure is indicated. Note: on the 1000 you don't have a switch to press because of the seleium cell.

The 1000 and 5000 have an interesting feature that works as a kind of mechanical shutter priority exposure mode. When you turn the shutter speed ring, the aperture setting ring turns in step with it. Thus, reciprocity is maintained while changing the speed setting. To actually change the exposure setting, you turn just the aperture ring. This can take some getting used to, but works relatively well.

One unique feature of the Lynx metering system, and used on all the models, is the carbon strip resistor located in the lens barrel. Most meters on cameras of this era use some type of variable size hole over the CDS cell to vary the amount of light seen by the cell. The Lynx system works instead by varying the resistance of the circuit using a series of pick-up brushes mounted on the shutter base. As the shutter speed, aperture ring or ASA setting is changed, the pick-up brush is moved along the resistive strip, thus varying the resistance of the circuit and the amount of current seen by the meter. Because this carbon strip can wear, the meters in these cameras can be off by 1-2 stops. The CDS cell on the Lynx is mounted on the camera body instead of in the lens barrel. This means that if you put a filter on the lens, you need to make a manual adjustment to the exposure. Also be aware that the CDS cell can pick up light reflected off the lens barrel. When shooting in bright sunlight, this can result in underexposure if you blindly follow the built-in meter. In the end you always have to use your judgement in addition to a built-in meter!

A very common problem on these cameras is an inoperative diaphragm. Because the aperture setting control is in the middle of the lens barrel, the control has to be linked to the diaphragm with a lever. This lever is easily bent and can pop out of the slot it fits into. Usually, an inoperative diaphragm can be fixed by simply removing the front lens and control rings, bending the lever back in place, and putting the controls back on the camera.

The camera shown here had the typical problems of inaccurate shutter, dirty and out of adjustment rangefinder, and corroded battery lead wire. I later found out that the self-timer was ruined and had to be replaced as well. It also had a badly damaged aperture control that needed to be replaced. Finally, all the grease in the focus had dried out (or more likely flushed out by an improper cleaning). As a result, the camera had to be almost completely disassembled. The camera was however in very nice cosmetic condition so I felt it was worth fixing rather than just using for parts. Fortunately, the Lynx is a relatively easy design to work on. Just try doing something like this on a Canonet some time and you really appreciate the simplicity of this camera's design!

For additional information, check out Joe Wolf's excellent Yashica site -- The Yashica Guy

|

To remove the top cover, open the back and hold the rewind fork while unscrewing the rewind knob. Watch for a washer underneath the knob. Unscrew the pinface screw in the wind lever and then lift off the spring washer, wind lever, cam, and shim. Remove the screws in the side of the top cover and lift the cover off. The screw in the back is only a rangefinder adjustment cover and can remain in place. The release button has a pin inside it that may fall out. Often, this pin has a small amount of grease on it that will cause it to stay in place. Turn the top cover over and you see a strip of light seal foam next to the meter display window. Usually this foam is rotten and needs to be replaced. The accessory shoe cover is removed by lifting up the front edge and sliding the cover back. |

|

The bottom cover is held by two screws. The battery cover can remain attached. When removing the cover, watch for the door latch release lever. This lever has a spring attached to it and will swing out of place when the cover is removed. There is a washer on the button and if you are not careful the washer will fly off as the spring pushes the lever out of place. |

|

This image shows the rangefinder adjustment screws. The screw in the back adjusts the horizontal matching. The screw on the side moves the mirror to adjust the vertical matching. There are often shims behind the mirror to adjust for variations in mirror width. If you install a new mirror, you may need to remove or add shims to get the vertical matching correct. You may also find it necessary to slightly bend the bracket holding the mirror to get it flush against the adjustment screw. The black paper cover over the rangefinder is glued in place. Just slide a knife blade along the edge to remove the paper and give access to the lenses for cleaning. |

|

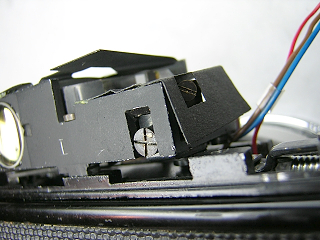

This image is a closeup of the meter. Note the small mirror sitting at an angle behind the meter needle. This mirror provides illumination for the meter needle and causes the needle position to show in the viewfinder. Often this mirror is missing. You can replace the mirror with anything shiny enough to reflect light into the viewfinder. I have used both aluminum foil and stainless steel shim material to do this and both work fine. The green colored glass is painted. It is not a good idea to try and clean this as the paint will easily rub off. |

|

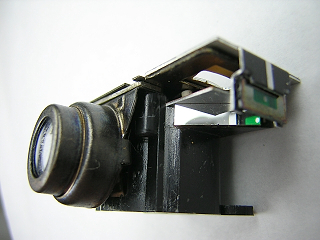

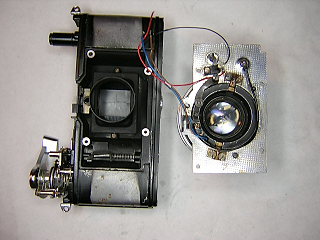

To remove the shutter from the camera, first unsolder the wires at the meter, making a drawing of the position of each wire. I find it difficult to get a soldering iron in to work on the meter, so I usually just remove the meter first. The meter is held by two screws at the back. Peel back the leatherette on the front to expose the four screws. Remove the screws and then carefully lift the mounting plate off the camera. The battery lead wire is connected to the switch on the front. Unsolder the black lead wire and the entire shutter and lens is then free from the camera. The red wire can remain attached. Back out the screw on the wiring bracket to get the wires free.and then unsolder the flash connector wire. Unscrew the rear lens and then unscrew the shutter retaining ring and the shutter will lift out of the mounting plate. You need to pull the wires through as you lift the shutter off. There is a light seal around the rear lens. This will almost always be rotten and need to be replaced. On every Lynx I've worked on, the shutter retaining ring was screwed in extremely tight. Apparently these rings are installed before the paint is set and are thus "glued" in place by the paint. Try running some laquer thinner or acetone around the ring to loosen the adhesion. This picture shows the rangefinder removed. I did this to make repairs on the rangefinder. Normally, the rangefinder can remain in place. |

|

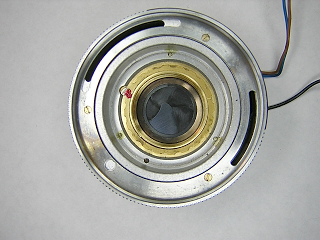

To disassemble the shutter, start by unscrewing the front lens. Set a friction tool against the inner chrome ring and turn it. The lens and ring will come out as a unit. |

|

The filter ring unscrews as well. If you are not going to disassemble the speed and aperture control, the filter ring can remain in place. |

|

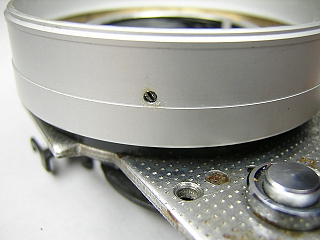

Turn the lock screw 1/2 turn until the flat side faces towards the center then unscrew the serrated retaining ring. The controls can then be lifted off the shutter. When lifting the controls off, be careful not to bend the wiper springs attached to the shutter base. The three screws visible from the front hold the speed control ring to the resistor ring. Don't remove these screws at this point. These screws can be loosend and the resistor ring turned slightly to make adjustment to the meter. It's a good idea to mark the position of the resistor ring if you intend to disassemble these pieces. |

|

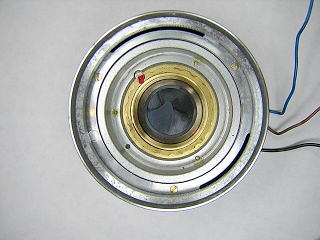

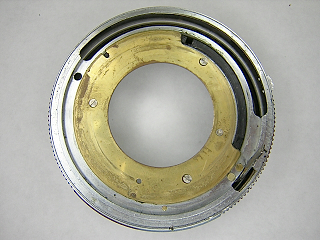

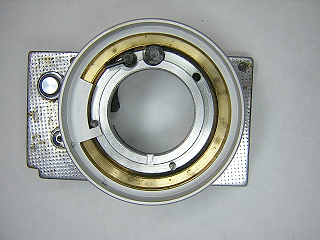

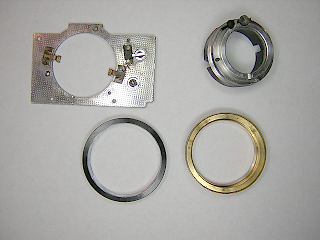

To disassemble the aperture, turn the shutter over and remove the three screws in the brass plate. Note the position of the gap in the plate relative to the hole in the black inner tube. This picture shows the plate at the B position. Lift the plate off and the interior aluminum tube will also come out from the front. These three screws are slightly different in length than the three screws that hold the shutter speed ring in place. The first Lynx I worked on I got the screws swapped. When that happens, the lens will not screw all the way in. It probably took me a day to figure out what I did wrong, so make sure not to mix up the screws. Extending out of the aperture ring is a lever that extends back through the shutter to operate the diaphragm. Although difficult to see in this picture due to the angle, this lever is badly bent on this camera. Most Lynx cameras have this problem to some extent. The lever is soft metal and easily bent so you can carefully bend it back straight. However, the lever will often break loose from its studs in the aperture control ring. If this happens, just reattach the lever with super glue after bending it straight. On this camera, the lever was so badly bent that the aperture control ring was damaged. You may have to straighten this ring as well. I had a spare from a junk camera, so I just replaced the ring rather than try to bend it back straight. |

|

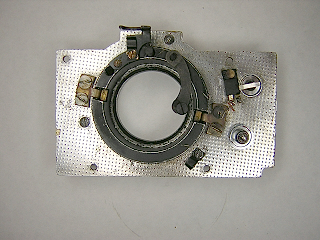

The aperture ring is held in place by two flat metal springs (see next picture) and simply lifts off.

|

|

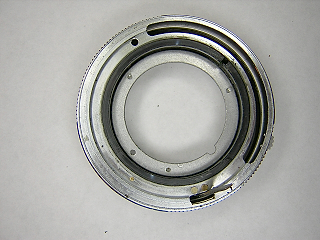

This picture shows the aperture ring separated from the shutter speed ring. Note the two flat springs riveted to the black inner tube. The purpose of these springs is to move the aperture ring when the shutter speed is changed so that the exposure value remains constant. The tension of these springs has to be strong enough to overcome the resistance of the diaphragm but light enough to slip when the diaphragm reaches the end of its travel. This little feature is what causes so much problem with the diaphragm control lever. These two pieces are easy to take apart, but can be quite difficult to reassemble. I'm always tempted to just break off the springs. Turn the shutter speed ring back over and remove the screws from the front. The pieces will then separate. Look at the inside of the resistor ring and you see a strip of carbon that provides the resistor for metering. This strip will sometimes develop dead spots and can also come loose. I avoid trying to clean this strip since doing so tends to remove some of the carbon. You need the appropriate electrical cleaner to clean this properly. |

|

This picture is a closeup of the ASA click stop and ASA wiper inside the aperture ring. To remove the ASA ring, pull back the click stop spring and remove the steel ball. Lift the ASA ring out and then remove the click stop spring. Be very careful around the wiper. It is very thin metal and easily bent. If you bend it, straighten it back before reassembly. Check for corrosion on this wiper and clean it if needed. This wiper is key to the metering system. The battery + side is electrically connected to this wiper through the battery cover, camera body, front mounting plate and shutter housing. As the aperture ring is rotated, this wiper moves along the resistor strip and varies the amount of voltage that is picked up by the two wipers attached to the shutter housing. Rotating the shutter speed ring moves the resistor past the two wipers also. |

|

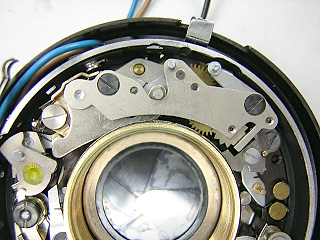

This picture shows the shutter mechanism. The Copal SV shutter is very similar to the Copal MXV shutter. Note the two wipers at the top of the shutter base. These wipers have to slide into slots in the shutter speed control ring during reassembly. Be careful not to bend them, and clean them if they show signs of corrosion. |

|

This picture is a closeup of the escapement retard. Unlike the MXV this escapement only has two screws holding it to the base. You remove the screw at the top in the cover and the screw at the base next to the pallet. There are shims underneath the assembly. Usually a slow shutter indicates that there is dried lubricant and dirt in the mechanism. You clean and lubricate it and the shutter comes back to proper speed. On this shutter, the slow speeds were too fast. Although it may sound strange, that is also usually caused by dirt and dried lubricant. Look at how the pallet sits on a lever that is held back by a stud on the blade operating ring. When the shutter fires and the speed cam is set to the slow speed range, this lever has to swing into place fast enough so that the pallet is engaged before the mainspring unwinds past the retard. If this lever is sticking, the pallet won't move into place and the shutter will run fast at the slow speed settings. A complete cleaning solved the problem and the shutter now runs perfectly at one second. |

|

From the back of the shutter you see the diaphragm control plate. There is a slot in the edge of this plate that must mate with the lever attached to the aperture control ring. The slot is at the lower right in this picture. This slot can get bent so that the lever will not sit properly inside it. Bend the small tabs if needed so that the lever does not pop out of the slot. In order to separate the shutter halves, remove the three screws holding this plate and then lift the plate off. Remove the screw holding the M/X selector. After that, disassembly is essentially the same as for the MXV shutter. |

|

To disassemble the focus helicoid, start by removing the two screws in the focus knob then lift the knob and focus scale off. This picture shows the focus ring rotated against the infinity stop. You may want to mark the infinity position of the brass ring before disassembling further. |

|

Back out the setscrews in the side of the focus control ring and lift the ring off. At this point you should carefully measure the height of the brass ring above the base. This will help determine the proper location during reassembly of the helicoid. |

|

Turn the front plate over and remove the rangefinder coupling bracket and the three screws holding the helicoid to the front plate. The entire assembly will then separate from the front plate. Look at the shutter release lever. There is an eccentric post on the end of the lever. You can turn this post with a screwdriver to change the position of the shutter release. The guides can remain attached to the front plate. This picture shows a bracket at the bottom where the flash wire goes. This was put there inadvertently and is not supposed to be there. |

|

Unscrew the helicoid from the black outer ring and then separate the inner and outer helicoid pieces. Count the number of turns and note the position where each of the rings separates. It will make it easier to reset the focus after reassembly if you reposition the pieces at their original position. |

Notes

To adjust focus, remove the focus knob and scale. Turn the focus ring until the image is sharp at infinity. Back out the setscrews around the focus ring and rotate the ring clockwise against the infinity stop. Re-tighten the setscrews and reinstall the knob and scale. When installing the scale, put the screws in the knob in slightly loose, then position the scale so that the infinity symbol is properly aligned. Slide along the scale to remove any slack and then tighten the focus knob screws.

To adjust the rangefinder horizontal alignment, remove the cover screw in the back of the top cover. Insert a screwdriver and turn the eccentric until the images align. Note that this is not a screw and does not tighten. The eccentric moves a bracket back and forth to turn the pivoting mirror. Vertical alignment can only be adjusted with the top cover removed. Turn the screw on the back of the mirror until the vertical alignment is correct.

It is possible to make slight adjustement of the meter alghough I've never had to do it. Unscrew the front lens and filter ring and then loosen the three brass screws. Slide the resistor ring back and forth until the meter reads correctly.

If the shutter release button does not fire the shutter, you can rotate the eccentric located on the release lever attached to the helicoid. Obviously this can only be done after removing the front panel. Small adjustments can be made by removing the bottom cover and turning the release shaft with a screwdriver. When making this adjustment, check to make sure that the winder lock releases at the same time as the shutter. Press the shutter button slowly and listen for a soft click sound. If you hear the click before the shutter releases, the winder lock is resetting too early. If the shutter fires before the winder unlocks, the winder lock is resetting too late. Turn the screw in the release shaft until the two actions happen simultaneously.